Cheese Making at home. But why?

Because we can and why not? It’s the challenge, the creativity, the sheer alchemy of taking milk and creating something so varied as cream cheese, cheddar or a blue cheese from the same basic raw ingredients. It’s the technical nature of it and the fact that I can make an excellent cheese that never fails to impress family and friends and me at least. It’s also a love of all things fermented, with the possible exception of Sauerkraut.

With what?

All you need is milk, bacteria, rennet and possibly some mould. You also need a bit of equipment which you can buy or improvise by making your own.

Milk

Milk is basically a suspension (or emulsion) of protein (Casein), sugars (lactose) and fat in water. Cheese is a coagulation of Casein with fat trapped within the coagulated structure. Most milk sold to domestic consumers in the UK is pasteurised and homogenised. Pasteurised is fine; it gives a layer of safety against potentially dangerous contamination and does not seem to affect the cheese production. However, homogenisation, where the fat globules have been broken up in order to distribute them throughout the milk and the cream no longer rises to the top, leads to a curd that is less firm which can make things difficult in some recipes.

Homogenisation is not fatal to making a good cheese but it is far from ideal and preferably I want milk that has not been homogenised. It can be full cream, semi-skimmed or even skimmed; cow, sheep or goat but it really needs to be unadulterated as much as possible. This is surprisingly difficult to buy if you shop in today’s supermarkets but it is possible.

I currently use Duchy organic milk (thanks Charles, I am very grateful for your quirky ways). This is not homogenised and is available from supermarkets such as Waitrose. Keep an eye on your chosen milk supply because they do change as I found out to my cost with Waitrose own brand organic when they suddenly started homogenising it.

Bacteria

Bacteria, mould and rennet perform the alchemy. Milk is warmed to a given temperature and the bacterial culture is added. The culture generally consists of mixed strains of Lactobacillus which break down, or ferment, the sugar (lactose) in the milk to produce lactic acid. This acidification of the milk together with the rennet causes the milk solids to coagulate and separate from the whey. More on acidification and its preservative properties in Charcuterie with the making of Salami.

Mould

Moulds, as in organisms which are in the same group as fungi as opposed to the containers in which the cheese is shaped, will be familiar to anyone who has eaten Camembert, Brie or Stilton. The white mould on a Camembert is produced by Penicillium camemberti. The blue mould and internal marbling of a Stilton is produced by Penicillium roqueforti.

Rennet

Rennet is a mixture of enzymes (which in themselves are proteins) which coagulate milk in acidic conditions. Rennet, therefore, works with the bacteria which acidify the milk through the production of lactic acid. The rennet enzymes are able to alter the structure of the casein protein which causes it to stick together and coagulate to form the curds. Homogenised milk produces a weaker curd probably because the distribution of fat interferes with the coagulation of the protein. Some books recommend the addition of Calcium chloride to counteract the homogenisation. Calcium ions reduce the natural resistance of the proteins to coagulate.

Equipment

The key here is to improvise and be imaginative. It helped that I had a previous passion for brewing beer but now since I don’t (or cannot) drink enough beer to justify making it, I am using some of the same equipment to make cheese. As an aside, in my humble opinion beer is easier to make than cheese and is certainly quicker.

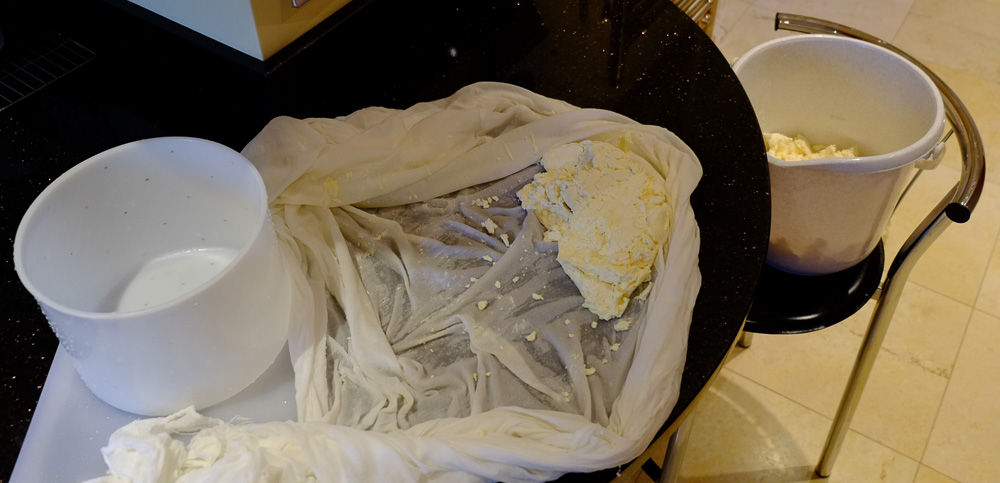

You will see that I use plastic 5 / 6-gallon buckets to contain the milk and a large boiling vessel as a water jacket. The buckets are cheap, the boiler was not cheap but you don’t actually need one, a large sink of pre-heated water would do just as well.

My cheese press is just squares of pine board fixed together at each corner with threaded steel rod. The curds are placed between the boards with a weight on the top board. The weight is a two-gallon beer barrel containing water; change the volume of water to vary the weight.

Moulds

Moulds, as in containers in which to form your cheese, can be improvised from any household plastic container or, as above, a large one purchased from a specialist supplier. Some cheeses, such as Cheddar or Lancashire are pressed in the mould but this blue cheese needs gaps between the pieces of curd to produce the blue marbling, so it is not pressed hard into the mould.

28 pints of milk did not make enough curd to fill the mould. I can only scale up to 40 pints at most. That would be a very heavy volume of milk and curds to handle but next time, maybe… or I may have to go back to a smaller mould and admit my limits.

After a few days in the mould, the cheese is released and I am always pleased that it manages to stay in one piece when it is turned out. The cheese is then placed in the maturation cave. In my case that is a wine fridge that I can set to about 13 to 15°c (also good for bottled beer). A damp, constant temperature, limestone cave would be better.

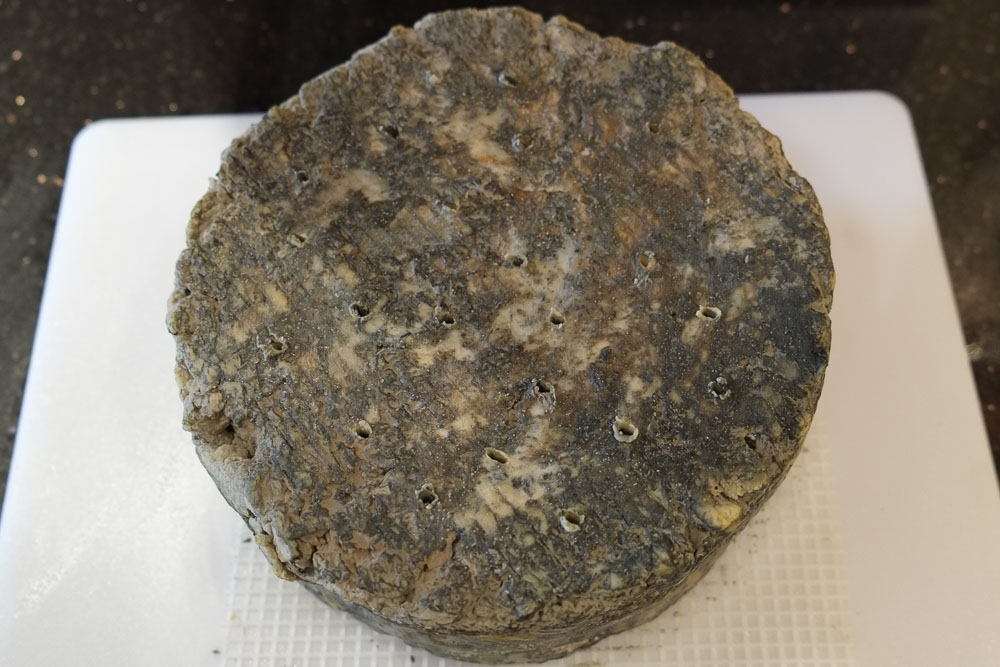

Humidity

After about 6 weeks it looks like this. I have wiped the mould off a few times with a damp cloth just to keep it under control. The key to keeping the mould growth under control and keeping the cheese from drying out and cracking is humidity control. 80% is about right and I can achieve this by keeping an eye on it and opening / closing the fridge door as necessary. Just wedging the door open slightly is enough to drop the humidity by a few percent.

Holes

After 6 weeks in the cave, some holes are poked through the cheese with a skewer. This allows air in and so the blue mould can form on the inside to produce the marbling.

Air

Keeping the air holes open is important, as close them up and you will have a cheese that is blue on the outside but white on the inside. In the cheese above the rind has encroached into the cheese through the holes; maybe they were too large or I poked the cheese too early. I am never entirely happy with the cheeses I make, it’s a bit like gardening, constantly planning your next season or your next cheese.

In pursuit of perfection

Here is a record of my attempts to perfect the blue cheese, from my first attempt in 2008. Click on an image to go to the post.

Recipes and resources

I have deliberately not set out to instruct you how to make cheese. There are far better resources out there than I can do here. However, here are some of the sources of information that I have used.

And here are a couple of my favourite recipes.

Websites

cheesemaking.com This is a US site so not so good for us Brits for supplies but a great resource for how to do things and recipes.

cheesemakingshop.co.uk/ A UK site where you can obtain anything from simple starter kits to micro dairies.

High Weald Dairy A family-run cheese dairy based on a farm in West Sussex. My wife and I attended one of their one-day courses on home cheesemaking and although I had been making cheese for a while I found the course hugely valuable and thoroughly entertaining. I cannot recommend them enough. They also make some great cheeses!

Books

These are the books I use for recipes and instruction. As with any recipe I do not necessarily stick to it religiously; I might mix and match between the two books and internet resources such as cheesmaking.com.

Home Cheese Making by Riki Carrol. Riki is the founder of the New England Cheesemaking Supply Company who’s website is cheesemaking.com

Making your own cheese by Paul Peacock. Paul has written 22 books that I have counted on Amazon on topics including allotments, bee-keeping, sausages, chickens, beer and of course, cheese. I also have, and recommend, his book on sausages.